-

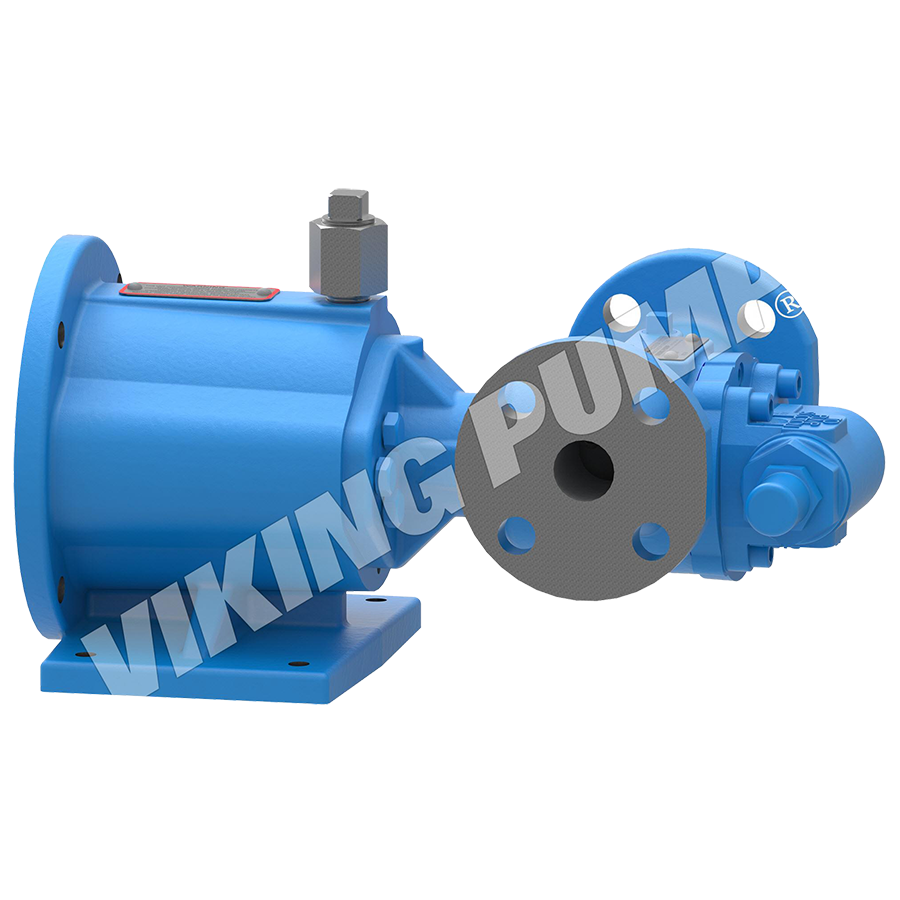

The 456 Motor Mounted units answer the need for more compact, lighter weight equipment. They use the Series 456 hub type pumps with valves in casings and are mounted to modified NEMA “C” flange motors. Units are available with ¼, ⅓, ½ or ¾ HP, 1 ph, 1200 RPM or 1800 RPM, special shaft, TEFC or explosion proof motors. All sizes use the mounting flange bracket with pump connected to motor through a coupling. The pump can be turned on the bracket to any position desired.

-

This advanced design is unique in its field for it permits use of STANDARD, unmodified NEMA C flange ball bearing motors.

-

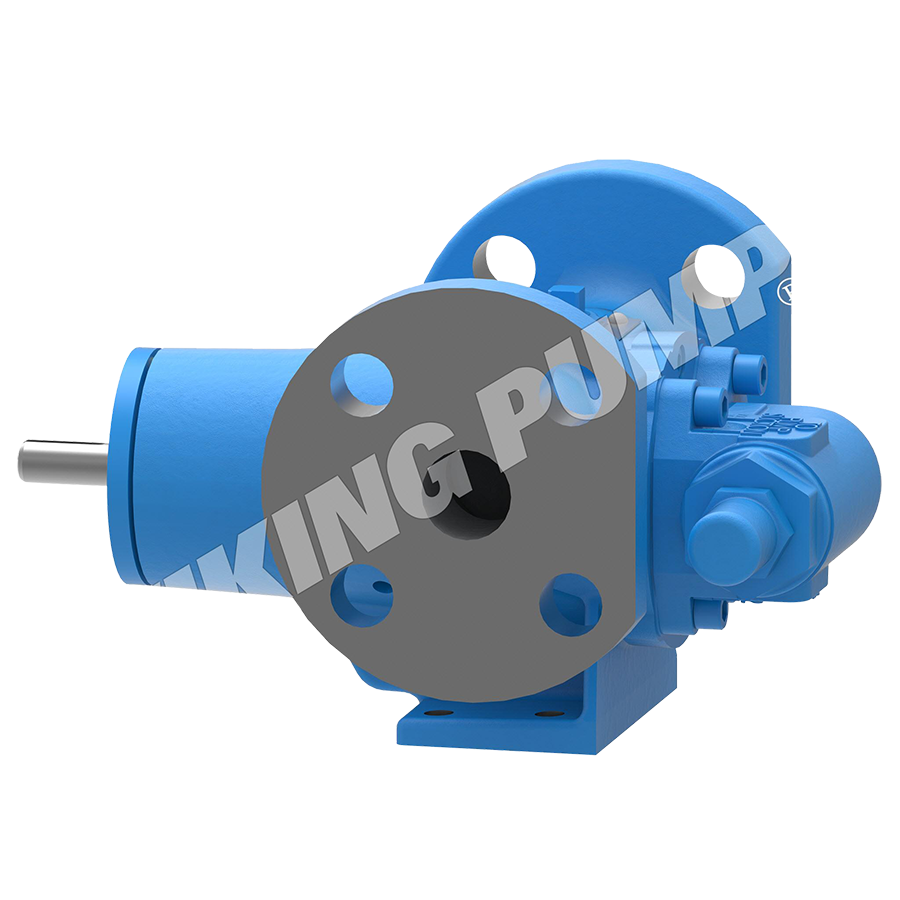

Series 493 is designed for vertical or horizontal flange mount installations where space is at a premium. Series 4193 is designed for foot type horizontal mounting. These pumps are built for continuous or intermittent duty for such applications as filtering, circulating, transferring, or booster service in general industrial, petrochemical and other industries.

-

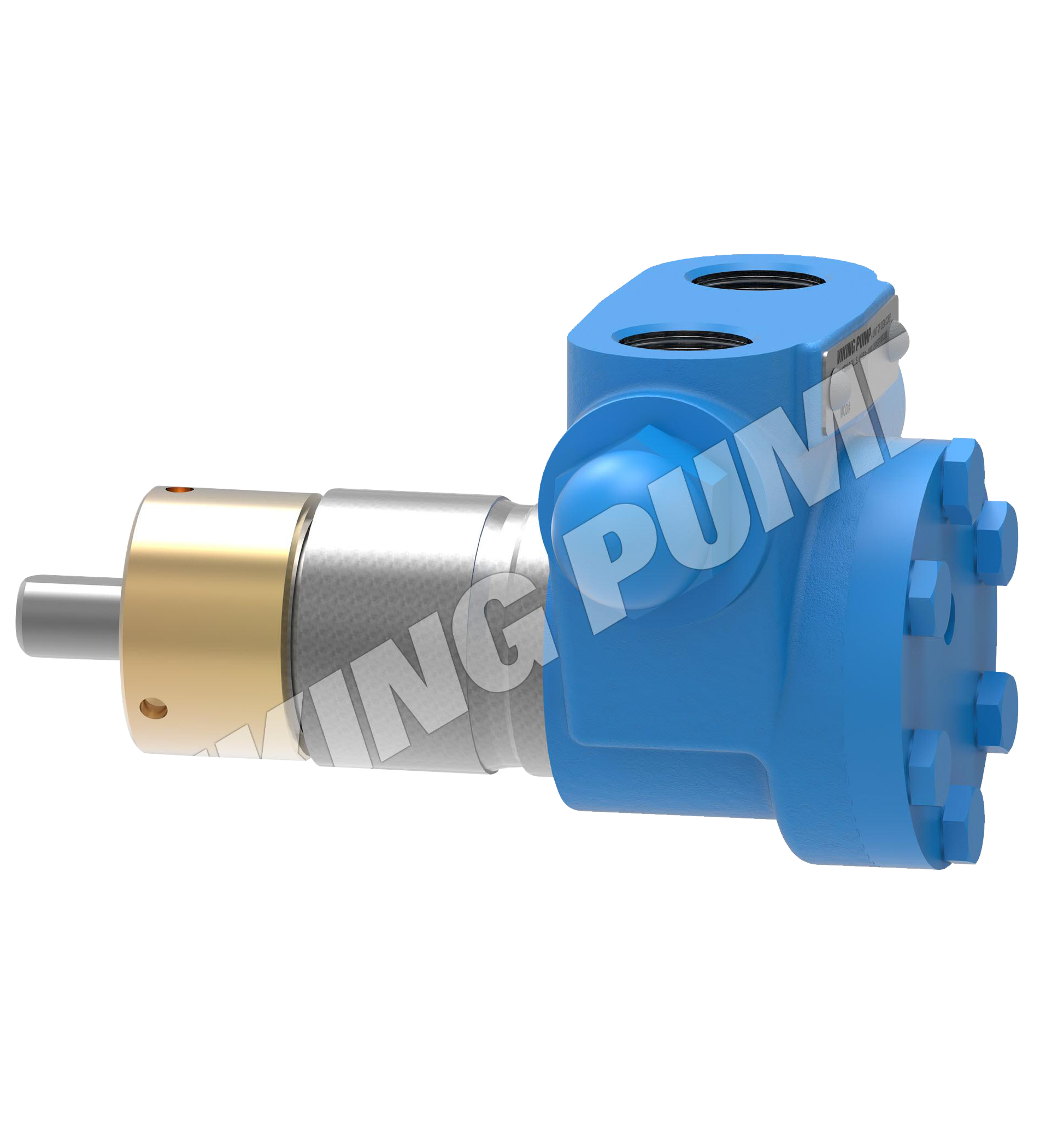

Viking’s Motor Speed Product Line internal gear pumps represent a technological advance in the science of flow. Through new techniques of feeding the rotor and idler, Viking has achieved what was once considered impossible - high flow rates operating at motor speeds. The largest size (QS) operates at reduced speeds, but still faster than other pumps of similar displacement. Higher speeds mean greater value, with the ability to move more fluid with a smaller pump. It also enables close-coupling to a motor or gear motor, which eliminates shaft misalignment and results in longer seal and bearing life by preventing wear due to misalignment.

-

For compactness, less weight and simplicity of mounting, Viking’s line of close-coupled pumps are ideal for direct connecting to other pieces of equipment. The positive, smooth delivery of these pumps makes them preferred for many types of applications including filtering, circulating, transferring, lubricating or booster service.

-

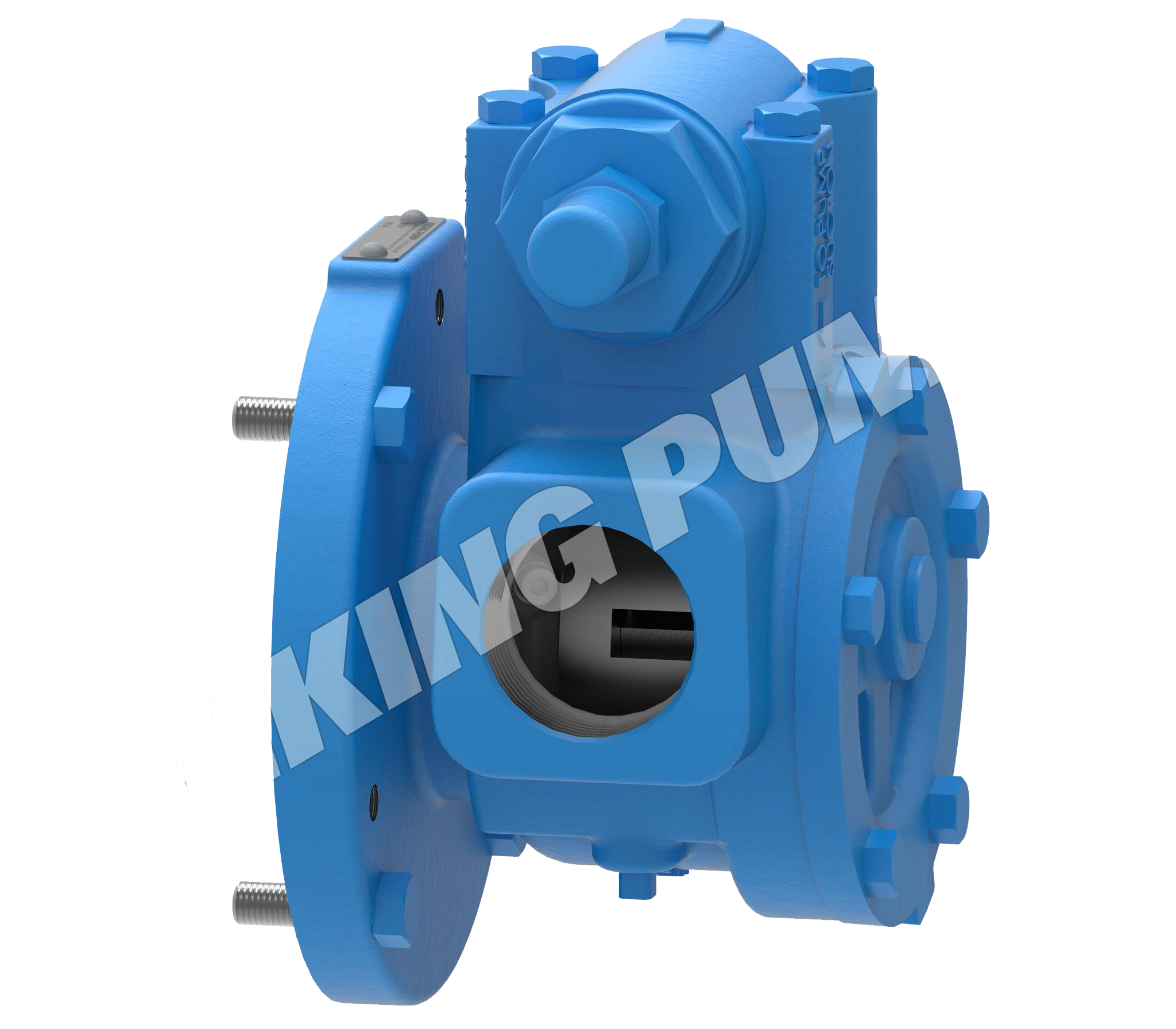

893 Series pumps are designed to provide positive displacement pumping capability in those situations that require the highest assurance of liquid containment. These mag drive pumps provide for the safe, trouble-free transfer of hazardous, EPA-regulated fluids without electronic monitoring as required with mechanical face-type shaft seals. Hard-to-seal liquids are also easily handled with the Viking Mag Drive which eliminates the high cost of mechanical seal replacement and repair. A variety of coupling sizes are available for flow requirements to 75 GPM. The torquecarrying ability of high-strength magnets allows pumps to be coupled with gear reducers for slow-speed handling of viscous liquids. The self-priming positive-displacement

pumping principle provides low-shear, non-pulsing flow. Internal gear pumps are available in stainless steel, steel, and cast iron construction. -

895 Series pumps are designed to provide positive displacement pumping capability in those situations that require the highest assurance of liquid containment. These mag drive pumps provide for the safe, trouble-free transfer of hazardous, EPA-regulated fluids without electronic monitoring as required with mechanical face-type shaft seals. Hard-to-seal liquids are also easily handled with the Viking Mag Drive which eliminates the high cost of mechanical seal replacement and repair. A variety of coupling sizes are available for flow requirements to 75 GPM. The torquecarrying ability of high-strength magnets allows pumps to be coupled with gear reducers for slow-speed handling of viscous liquids. The self-priming positive-displacement

pumping principle provides low-shear, non-pulsing flow. Internal gear pumps are available in stainless steel, steel, and cast iron construction. -

897 Series pumps are designed to provide positive displacement pumping capability in those situations that require the highest assurance of liquid containment. These mag drive pumps provide for the safe, trouble-free transfer of hazardous, EPA-regulated fluids without electronic monitoring as required with mechanical face-type shaft seals. Hard-to-seal liquids are also easily handled with the Viking Mag Drive which eliminates the high cost of mechanical seal replacement and repair. A variety of coupling sizes are available for flow requirements to 75 GPM. The torquecarrying ability of high-strength magnets allows pumps to be coupled with gear reducers for slow-speed handling of viscous liquids. The self-priming positive-displacement

pumping principle provides low-shear, non-pulsing flow. Internal gear pumps are available in stainless steel, steel, and cast iron construction.