-

GEAR BOX: Powder-coated standard I 304 stainless steel optional

-

Customers, however, told us they wanted ONE pump to do it all. So we incorporated all of those features, and more, into our 1224A-CHC Series chocolate pumps to enable standardization of pumps and spares throughout the plant.

Whether the task is to transfer cocoa mass from a ball mill across the plant to a blending tank, or to recirculate yogurt coating in a closed loop to feed a series of panners, or to continuously recirculate tempered milk chocolate from an enrobing machine’s sump to the feed trough, or a hundred other possibilities, Viking’s gentle, reliable pumps will improve your operational efficiency -

The electrically heated pump is specifically designed to heat the asphalt within the pump, prior to start-up. Heat cartridges located on the bracket or casing heat the area behind the rotor and stuffing box. The design also uses heat cartridges installed in the head to quickly melt asphalt throughout the casing.

-

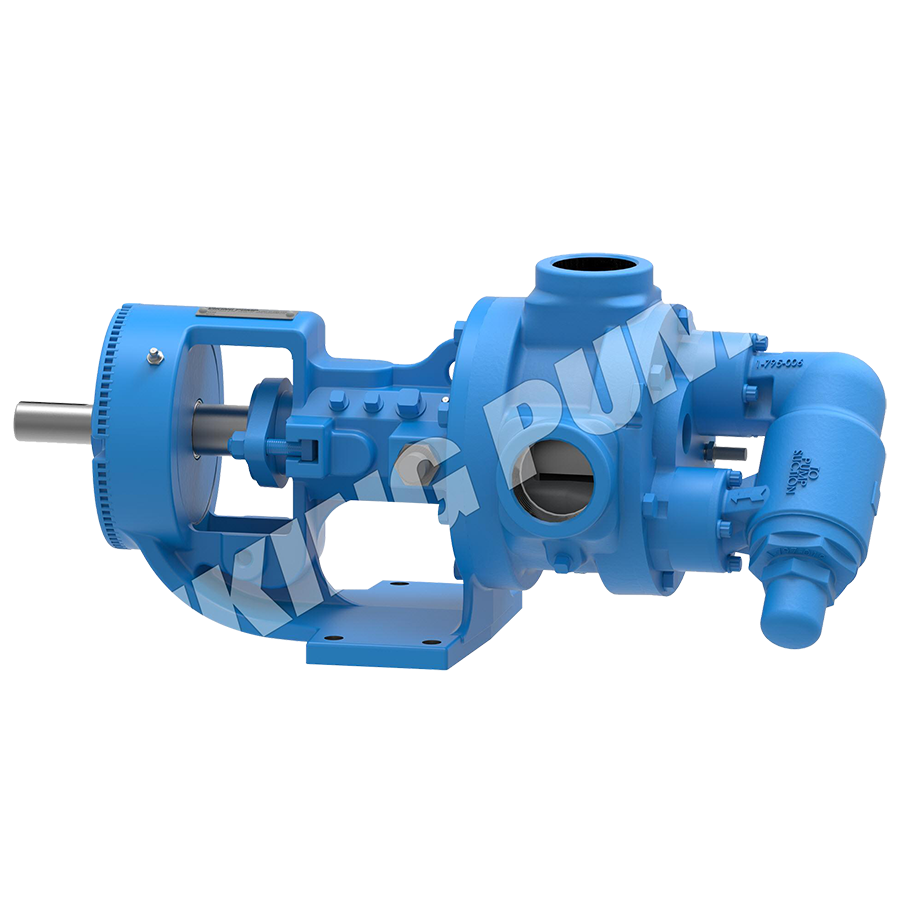

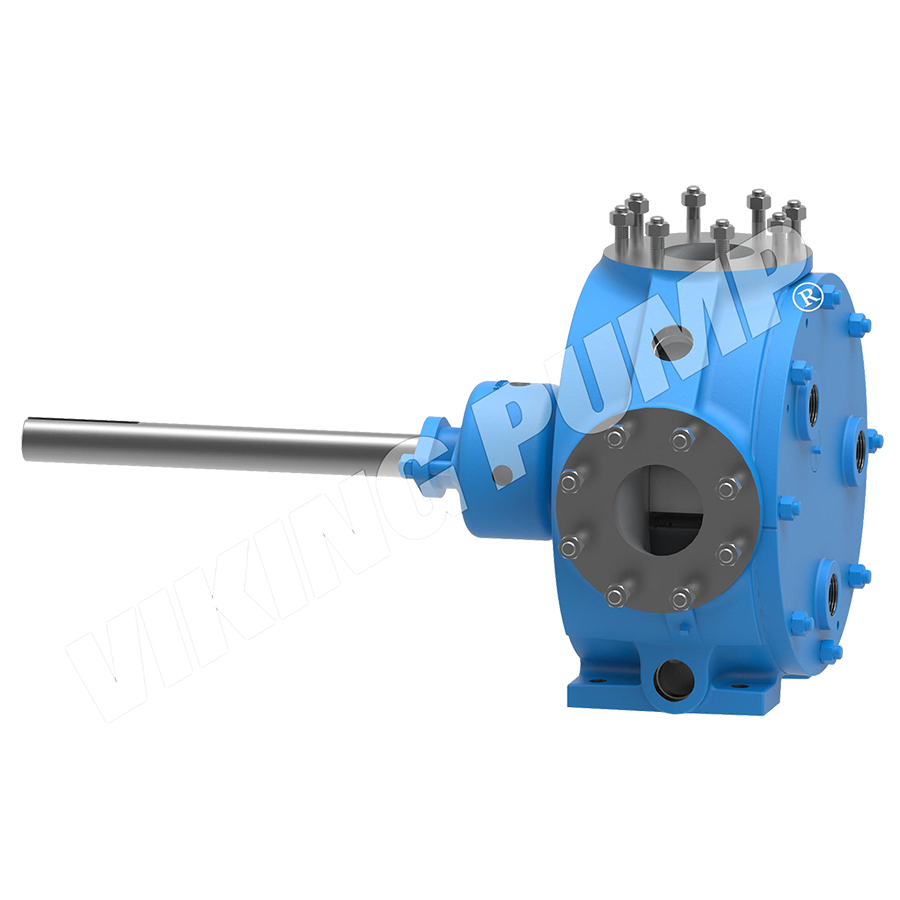

Viking 34 Series™ Asphalt Pumps are designed to handle asphalts, bitumens, pitch, tar, bunker oils, residual oils and related materials that solidify at ambient temperatures. The 34 Series™ pumps are Viking’s simplest asphalt pumps, with a hydraulically-balanced rotor that eliminates the need for thrust control, but also limits the pressures to 100 PSI and less.

These asphalt pumps melt ambient-temperature solids to a liquid state prior to pump startup using integral jacketing for steam or hot oil. The 34 Series™ are available as packed pumps only -

The 4197-SEP Series™ pumps are specially fit with low temperature materials suitable for subzero solvent transfer or circulation applications. They are also assembled and tested using only food grade liquids.

-

Viking 34 Series™ Asphalt Pumps are designed to handle asphalts, bitumens, pitch, tar, bunker oils, residual oils and related materials that solidify at ambient temperatures. The 34 Series™ pumps are Viking’s simplest asphalt pumps, with a hydraulically-balanced rotor that eliminates the need for thrust control, but also limits the pressures to 100 PSI and less.

These asphalt pumps melt ambient-temperature solids to a liquid state prior to pump startup using integral jacketing for steam or hot oil. The 34 Series™ are available as packed pumps only -

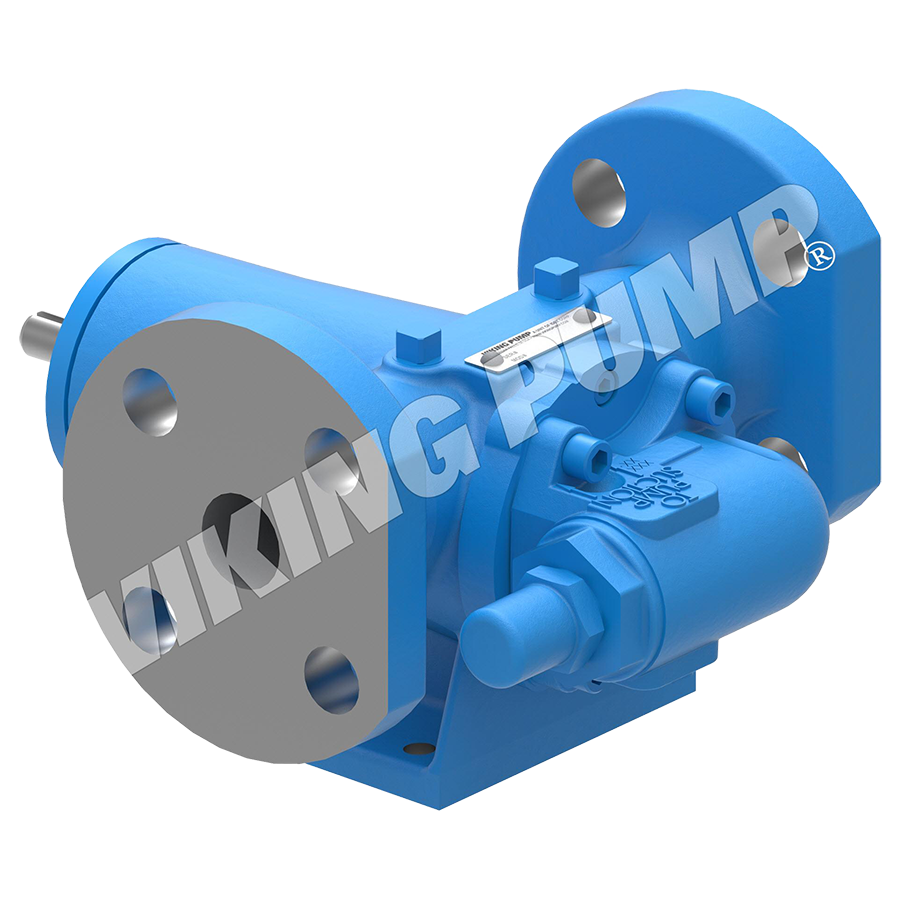

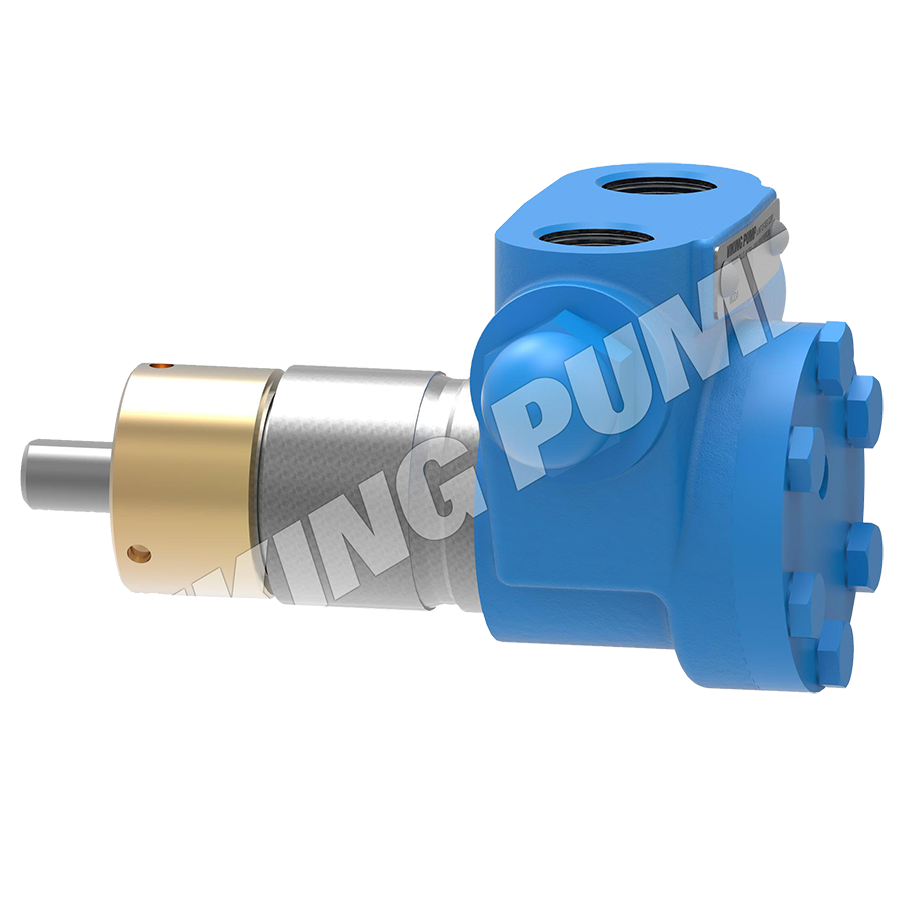

The 456 Motor Mounted units answer the need for more compact, lighter weight equipment. They use the Series 456 hub type pumps with valves in casings and are mounted to modified NEMA “C” flange motors. Units are available with ¼, ⅓, ½ or ¾ HP, 1 ph, 1200 RPM or 1800 RPM, special shaft, TEFC or explosion proof motors. All sizes use the mounting flange bracket with pump connected to motor through a coupling. The pump can be turned on the bracket to any position desired.

-

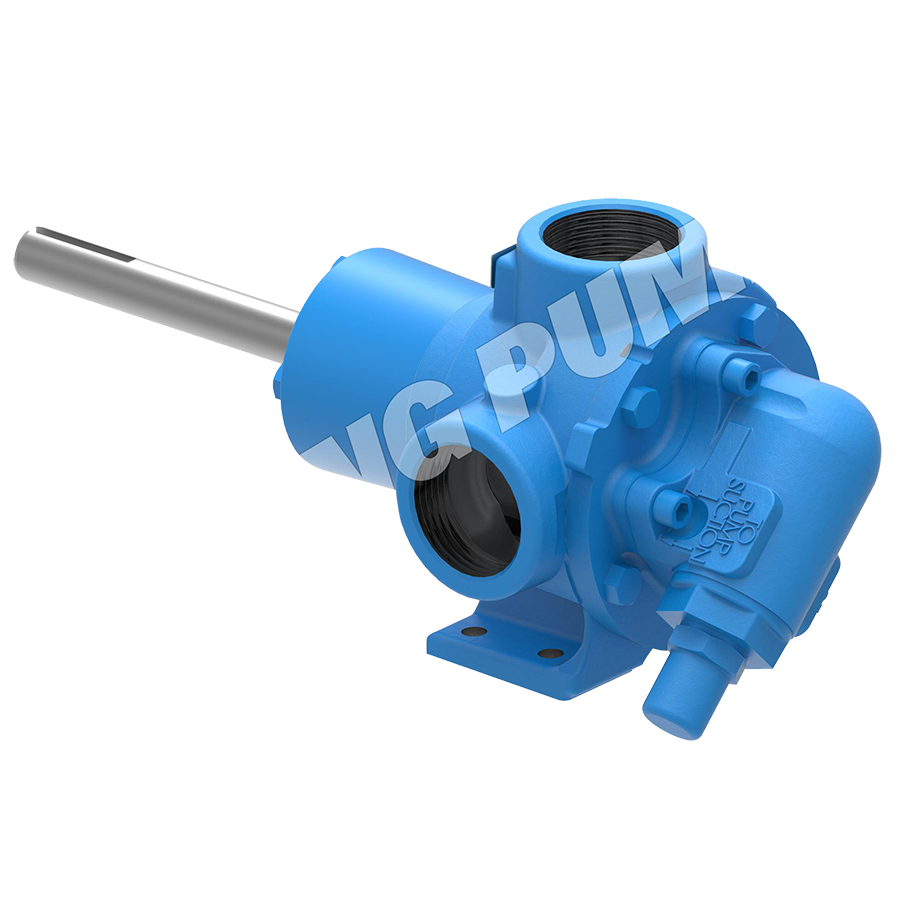

The 4624B Series™ internal gear pumps utilize hard parts in key wear areas, combined with unique designs and operating practices to reduce abrasive wear for longest life. These pumps are ideally suited for liquids with concentrations of small but hard particles, such as paints, inks and pigments; filled polyols and resins; and waste oils.