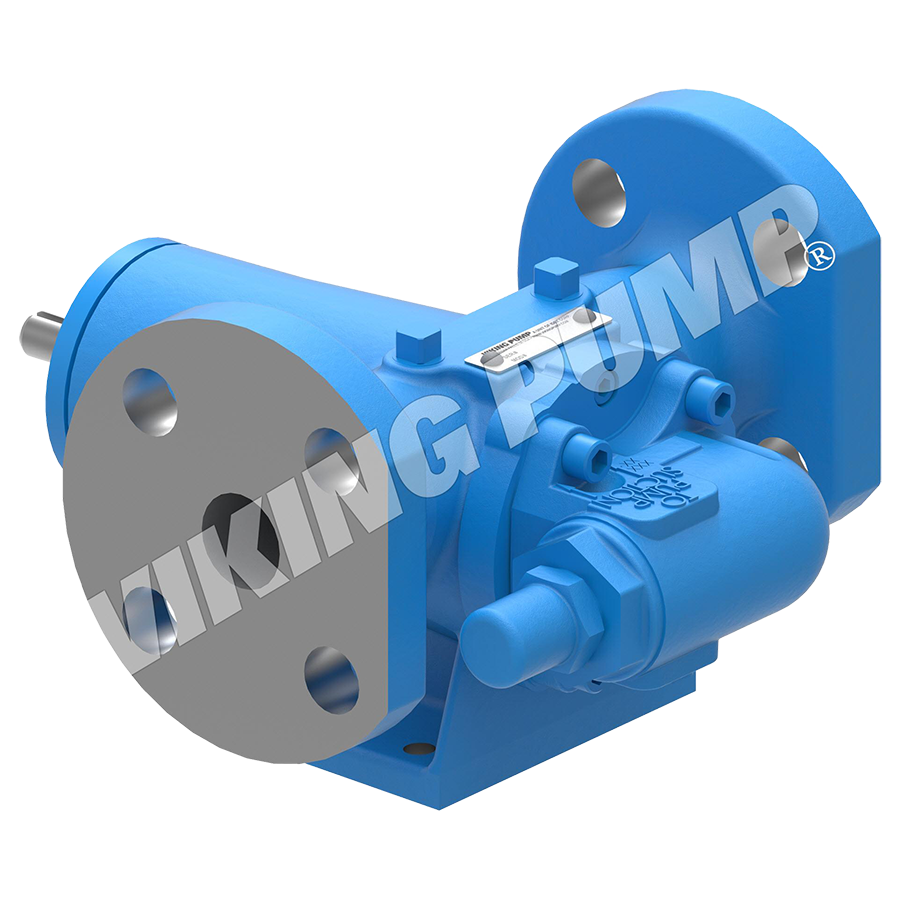

Universal product line

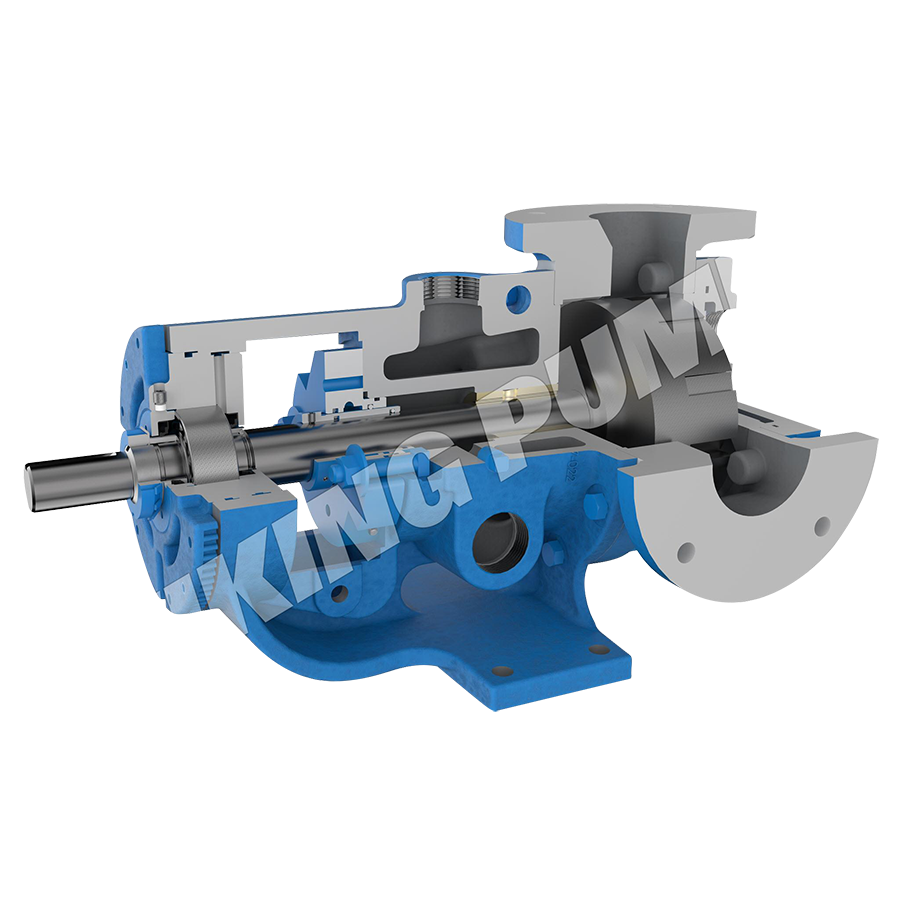

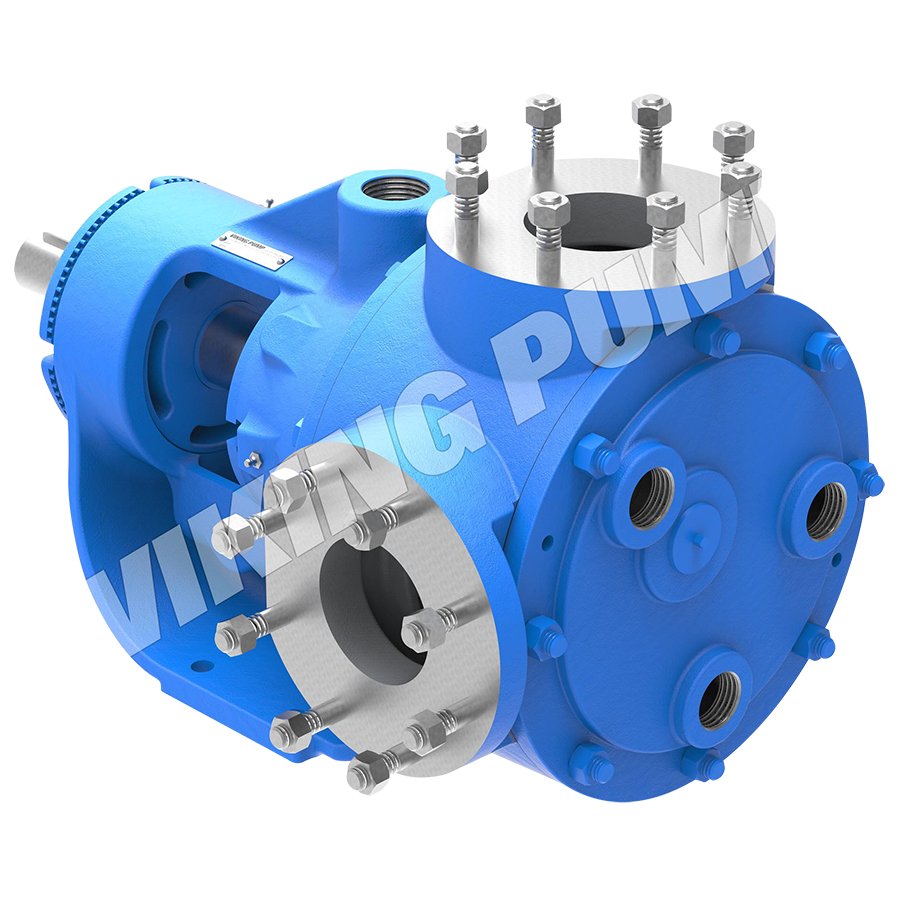

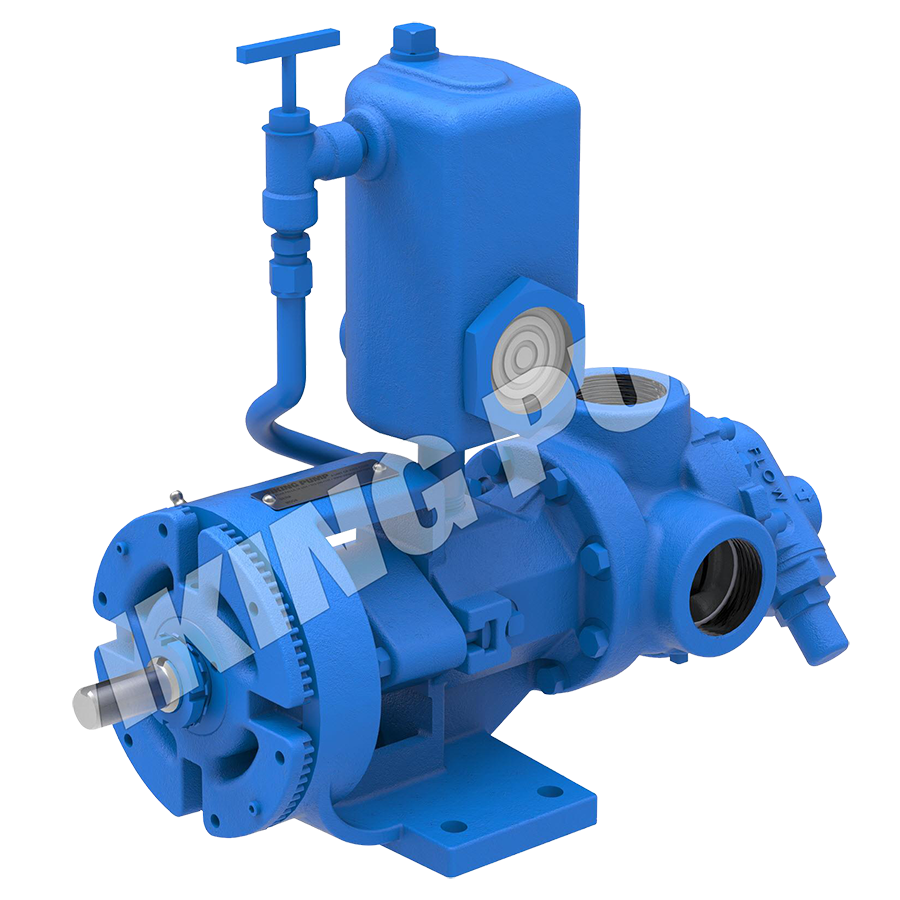

Viking Pump is the leader in internal gear innovation and the latest development is the O-Pro™ Seal technology. The NEW Universal Seal Product Line comes with the O-Pro Guard Seal factory installed. The Universal Product Line combines the tested reliability of the Universal pump & O-rings to create a robust seal and lubrication chamber, all in one.

Pumps are designed for a broad range of applications, from thin to thick, requiring continuous duty at pressures up to 200 PSI (14 Bar). Even higher pressures are possible with high fluid viscosities at reduced operating speeds (consult factory). They are also capable of operating under suction lift conditions and operate equally well in either direction.

The Universal Product Line has the broadest range of sealing options of all pumps built by Viking. The stuffing box on all sizes accepts packing, numerous component single mechanical seals, or a wide variety of cartridge seals.

The Universal Product Line is Viking Pump’s most versatile line of internal gear pumps due to the availability of many design and material options.

The Universal Product Line has the broadest range of sealing options of all pumps built by Viking. The stuffing box on all sizes accepts packing, numerous component single mechanical seals, or a wide variety of cartridge seals.

The Universal Product Line is Viking Pump’s most versatile line of internal gear pumps due to the availability of many design and material options.

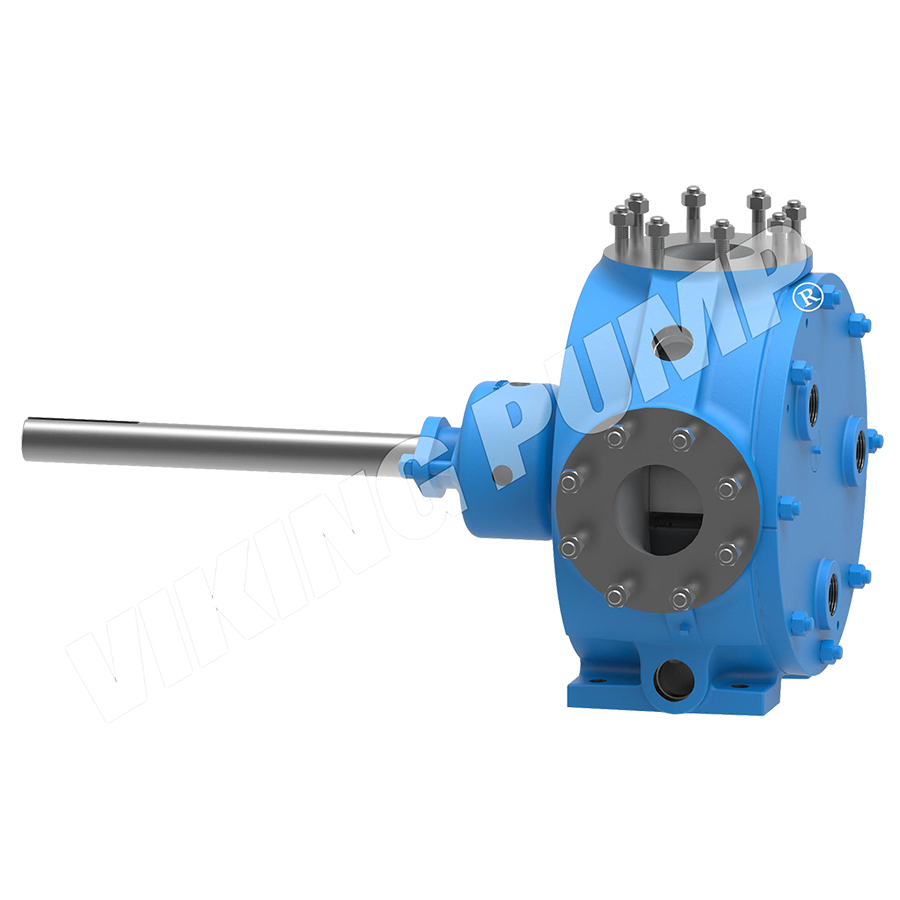

The 4124B series heavy duty internal gear pumps have Behind the Rotor dynamic shaft seals. By locating the mechanical seal immediately behind the rotor, this prevents the shaft and bracket bushing from coming into contact with the liquid.

The Universal Product Line has the broadest range of sealing options of all pumps built by Viking. The stuffing box on all sizes accepts packing, numerous component single mechanical seals, or a wide variety of cartridge seals.

The Universal Product Line is Viking Pump’s most versatile line of internal gear pumps due to the availability of many design and material options

The Universal Product Line is Viking Pump’s most versatile line of internal gear pumps due to the availability of many design and material options

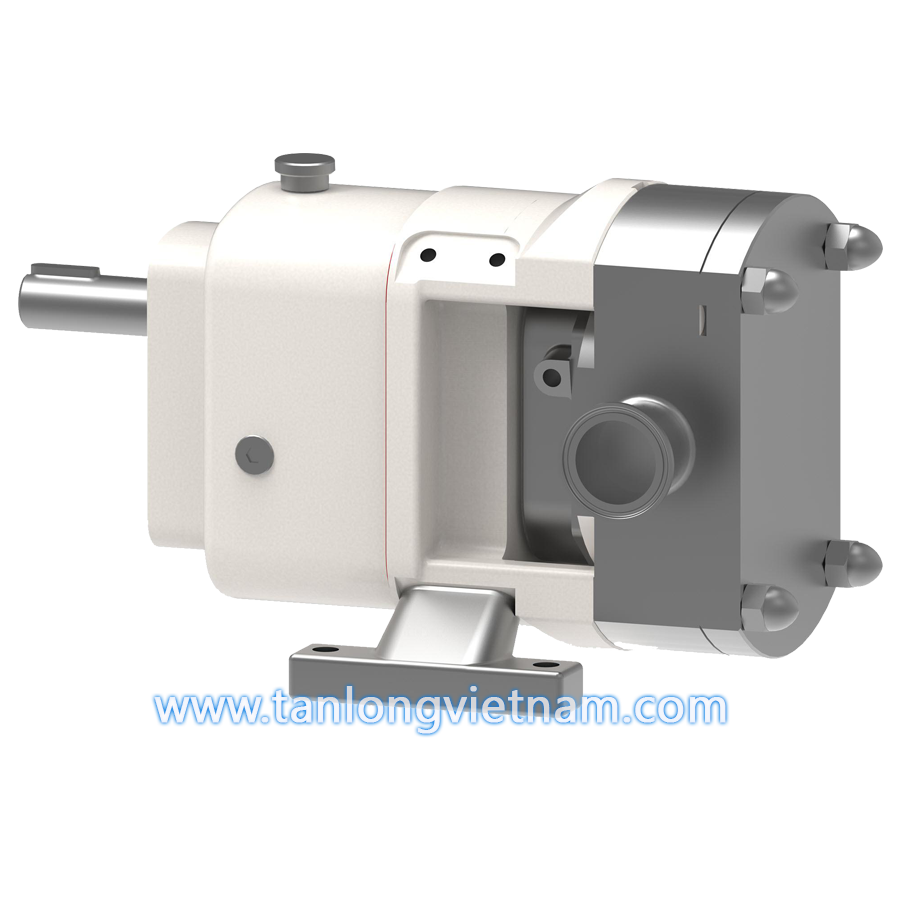

Hygienic Product Line

TR-C and other “C-Series” pumps can be converted to TR-C+ with a simple kit

For too long, cast iron pumps have compromised the integrity of chemicals carried in stainless steel road tankers. Designed specifically for the chemical transport industry, the RTPe stainless steel pump delivers that essential missing component. Better yet, it provides a cost-effective solution to this problem, while still outperforming the competition in both speed and reliability.

Based on the industry-leading hygienic RTP, the RTPe incorporates all of the features your chemical tanker needs, while eliminating those that it does not.

Protect your investment and make your chemical transport business even stronger. The RTPe is the essential component to complete your chemical tanker system.

Based on the industry-leading hygienic RTP, the RTPe incorporates all of the features your chemical tanker needs, while eliminating those that it does not.

Protect your investment and make your chemical transport business even stronger. The RTPe is the essential component to complete your chemical tanker system.

Standard bi-wing rotors offer application flexibility & good solids handling capabilities

Multi-lobe rotors reduce shear & pulsation effect; ideal for sensitive media

Innovative cusps with reliefs allow for easier cleaning and self draining with improved efficiency

Multi-lobe rotors reduce shear & pulsation effect; ideal for sensitive media

Innovative cusps with reliefs allow for easier cleaning and self draining with improved efficiency

Modular pump design promotes easy disassembly for COP (Clean Out of Place) & CIP (Clean In Place)

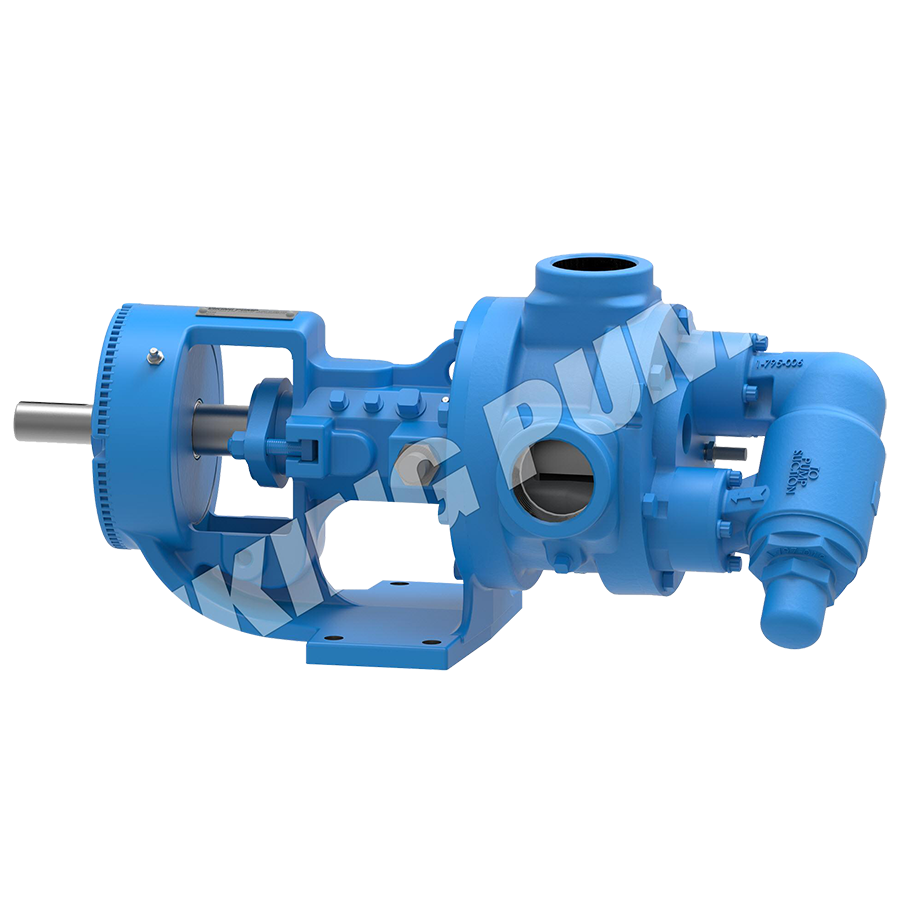

Liquid Specific Product Line

The 4197-SEP Series™ pumps are specially fit with low temperature materials suitable for subzero solvent transfer or circulation applications. They are also assembled and tested using only food grade liquids.

Viking 34 Series™ Asphalt Pumps are designed to handle asphalts, bitumens, pitch, tar, bunker oils, residual oils and related materials that solidify at ambient temperatures. The 34 Series™ pumps are Viking’s simplest asphalt pumps, with a hydraulically-balanced rotor that eliminates the need for thrust control, but also limits the pressures to 100 PSI and less.

These asphalt pumps melt ambient-temperature solids to a liquid state prior to pump startup using integral jacketing for steam or hot oil. The 34 Series™ are available as packed pumps only

These asphalt pumps melt ambient-temperature solids to a liquid state prior to pump startup using integral jacketing for steam or hot oil. The 34 Series™ are available as packed pumps only

The electrically heated pump is specifically designed to heat the asphalt within the pump, prior to start-up. Heat cartridges located on the bracket or casing heat the area behind the rotor and stuffing box. The design also uses heat cartridges installed in the head to quickly melt asphalt throughout the casing.

Viking’s 4924A Series™ Positive Displacement (PD) pumps offer safety, reliability and high efficiency in refrigeration ammonia recirculation applications. Safety is achieved through use of a double mechanical dynamic shaft seal located between bearings for minimum possible shaft run-out, with a pressurized barrier fluid system, and O-ring type static seals where components are joined. Reliability is provided by slow speed operation and low differential pressures, which maximize bearing and seal life. And efficiency is inherent in the PD Internal Gear pumping principle, compared to centrifugal pumps. Viking pumps can usually use at least one motor size smaller than these technologies.