-

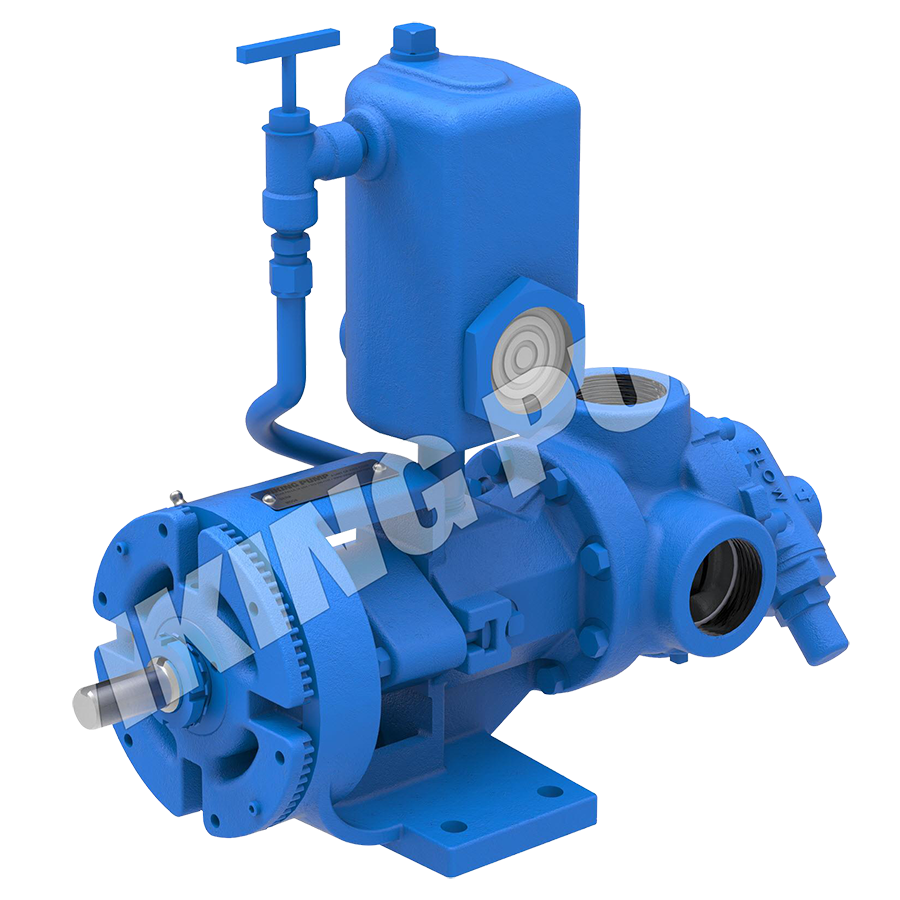

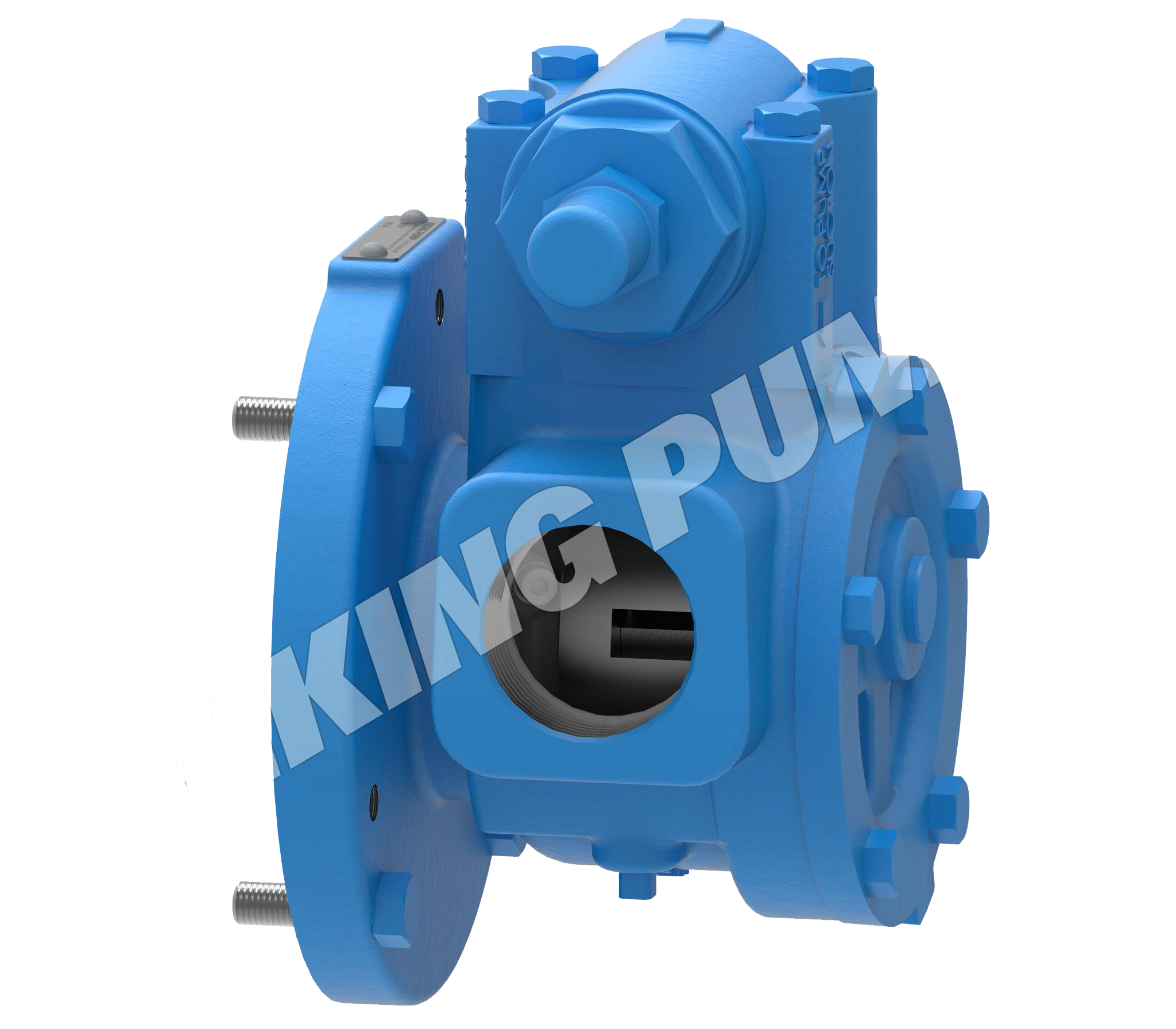

Viking’s 4924A Series™ Positive Displacement (PD) pumps offer safety, reliability and high efficiency in refrigeration ammonia recirculation applications. Safety is achieved through use of a double mechanical dynamic shaft seal located between bearings for minimum possible shaft run-out, with a pressurized barrier fluid system, and O-ring type static seals where components are joined. Reliability is provided by slow speed operation and low differential pressures, which maximize bearing and seal life. And efficiency is inherent in the PD Internal Gear pumping principle, compared to centrifugal pumps. Viking pumps can usually use at least one motor size smaller than these technologies.

-

Viking’s unique and unusually simple pump construction makes it adaptable to many diversified installations. The pumps possess excellent vacuum characteristics and will operate and prime at suction lifts up to 25 feet, depending upon the vaporization point of volatile liquids. Because of the cushioned action in providing a continuous and steady stream of liquid without splashing, pounding, foaming or churning, the Viking pump is adaptable to an unlimited number of industrial applications

-

Viking’s Motor Speed Product Line Series 493 and 4193 steel external pumps are available in capacities up to 75 GPM. These pumps can be furnished directly connected to a 50HZ or 60 HZ motor.

-

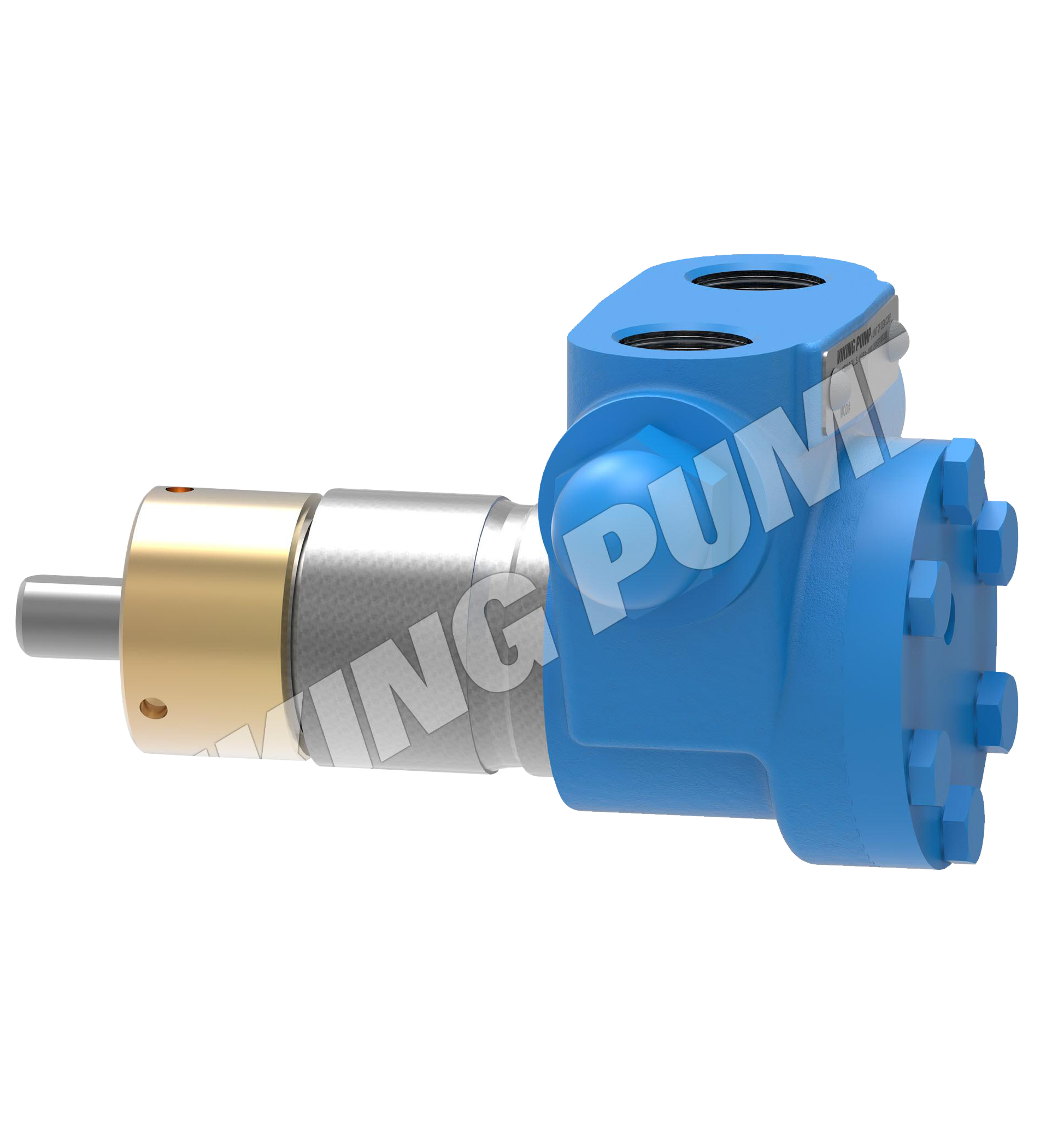

Giảm 33.33%Viking’s Motor Speed Product Line internal gear pumps represent a technological advance in the science of flow. Through new techniques of feeding the rotor and idler, Viking has achieved what was once considered impossible - high flow rates operating at motor speeds. The largest size (QS) operates at reduced speeds, but still faster than other pumps of similar displacement. Higher speeds mean greater value, with the ability to move more fluid with a smaller pump. It also enables close-coupling to a motor or gear motor, which eliminates shaft misalignment and results in longer seal and bearing life by preventing wear due to misalignment.

-

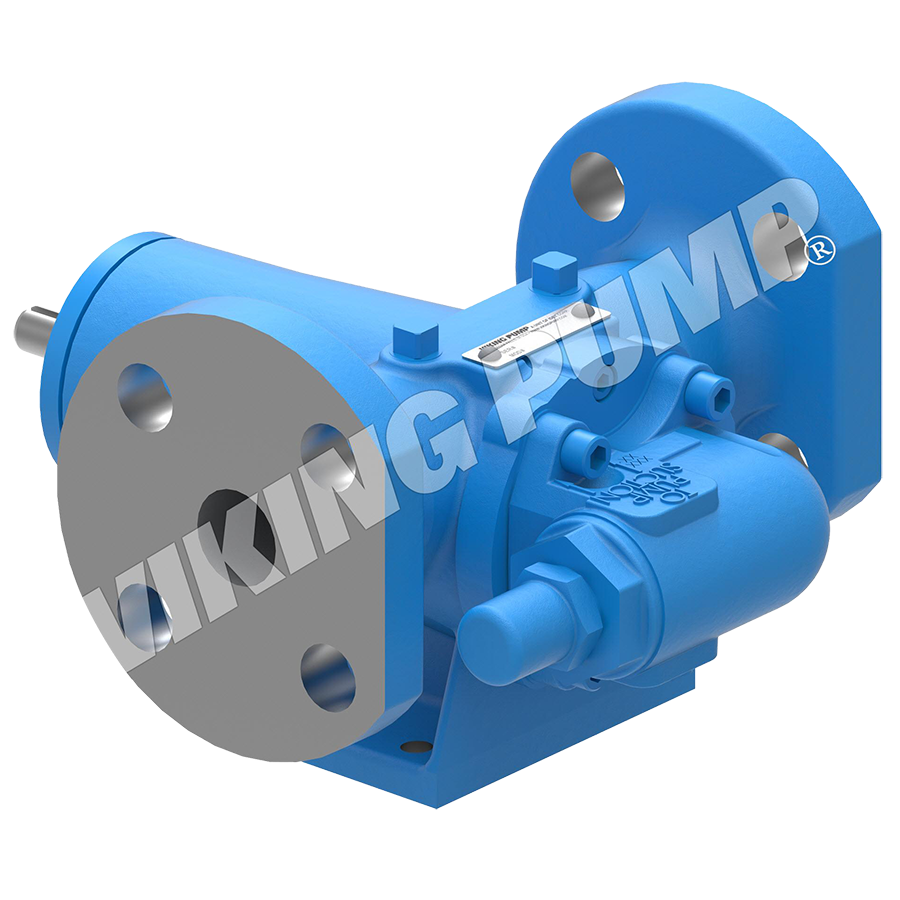

4197 Series™ and 4197-SEP Series™ pumps are designed for foot type horizontal mounting. These pumps are built for continuous or intermittent duty for such applications as filtering, circulating, transferring or booster service in general industrial, petrochemical, and other industries. The 4197-SEP Series™ pumps are specially fit with low temperature materials suitable for subzero solvent transfer or circulation applications. They are also assembled and tested using only food grade liquids.

-

Viking’s Motor Speed Product Line internal gear pumps are extremely well suited for light, medium and intermittent service handling a variety of liquids. The smaller sizes C, F, FH are constructed for heavier duty service. Mechanical seal equipped pump models in sizes C, F, FH, G, H, HL are available with Underwriters label for handling fuel oil. Model numbers for these pumps must be designated by a suffix -X.

UL listed models can be equipped with integral relief valve. Viking’s unique and unusually simple pump construction makes it adaptable to many diversified installations. The pumps possess excellent vacuum characteristics and will operate and prime at suction lifts up to 25 feet, depending upon the vaporization point of volatile liquids. Because of the cushioned action in providing a continuous and steady stream of liquid without splashing, pounding, foaming or churning, the Viking pump is adaptable to an unlimited number of industrial applications -

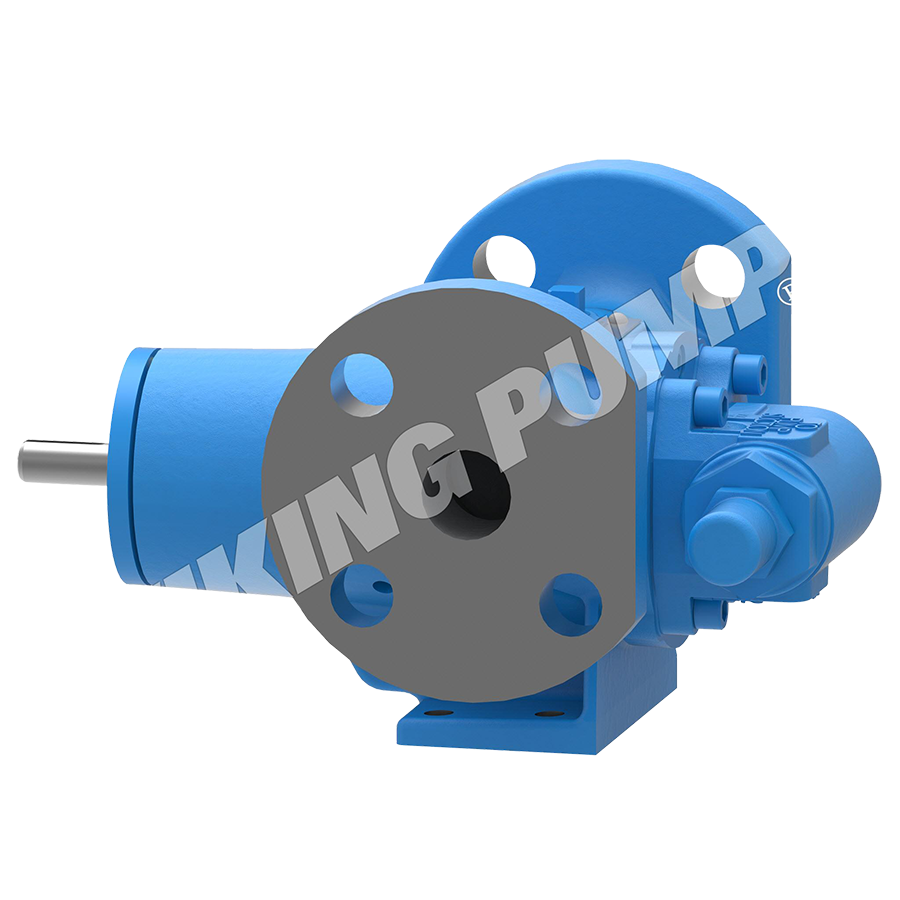

The 456 Motor Mounted units answer the need for more compact, lighter weight equipment. They use the Series 456 hub type pumps with valves in casings and are mounted to modified NEMA “C” flange motors. Units are available with ¼, ⅓, ½ or ¾ HP, 1 ph, 1200 RPM or 1800 RPM, special shaft, TEFC or explosion proof motors. All sizes use the mounting flange bracket with pump connected to motor through a coupling. The pump can be turned on the bracket to any position desired.

-

This advanced design is unique in its field for it permits use of STANDARD, unmodified NEMA C flange ball bearing motors.