Description

FEATURES & BENEFITS

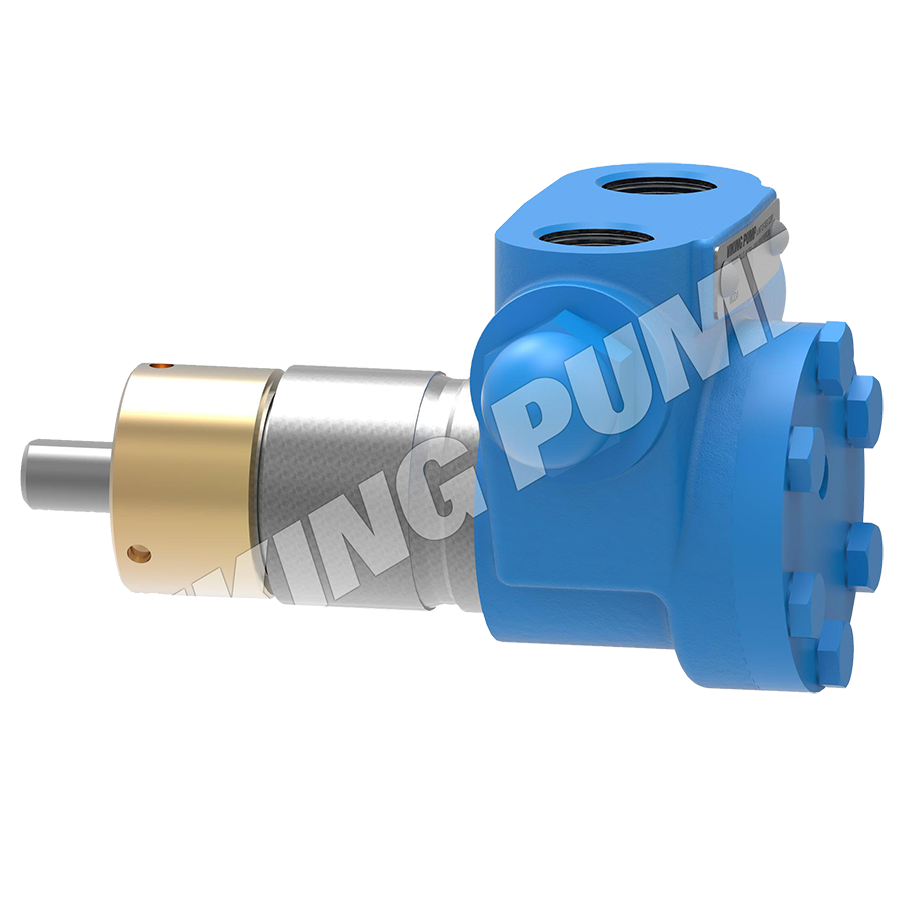

- Ultra-hard tungsten carbide idler pin and tungsten carbide idler bushing minimize wear in this key area, since a constant supply of abrasive material is flowing through the pumping elements.

- Behind-the-rotor pinned-seat mechanical seal with hard silicon carbide vs. silicon carbide seal faces, featuring external flush line from pump discharge to remove solids build-up, ensuring longest possible seal life (note: no flush line on F & FH sizes).

- The grease-lubricated bracket bushing is not contacted by the pumped liquid, for long life. The pump is re-greasable, with a lip seal at the stuffing box to retain grease and a relief fitting to prevent over-greasing.

- The grease-filled bracket helps to prevent air and moisture from reaching the seal faces, which helps limit crystallization of some air or water-reactive liquids.

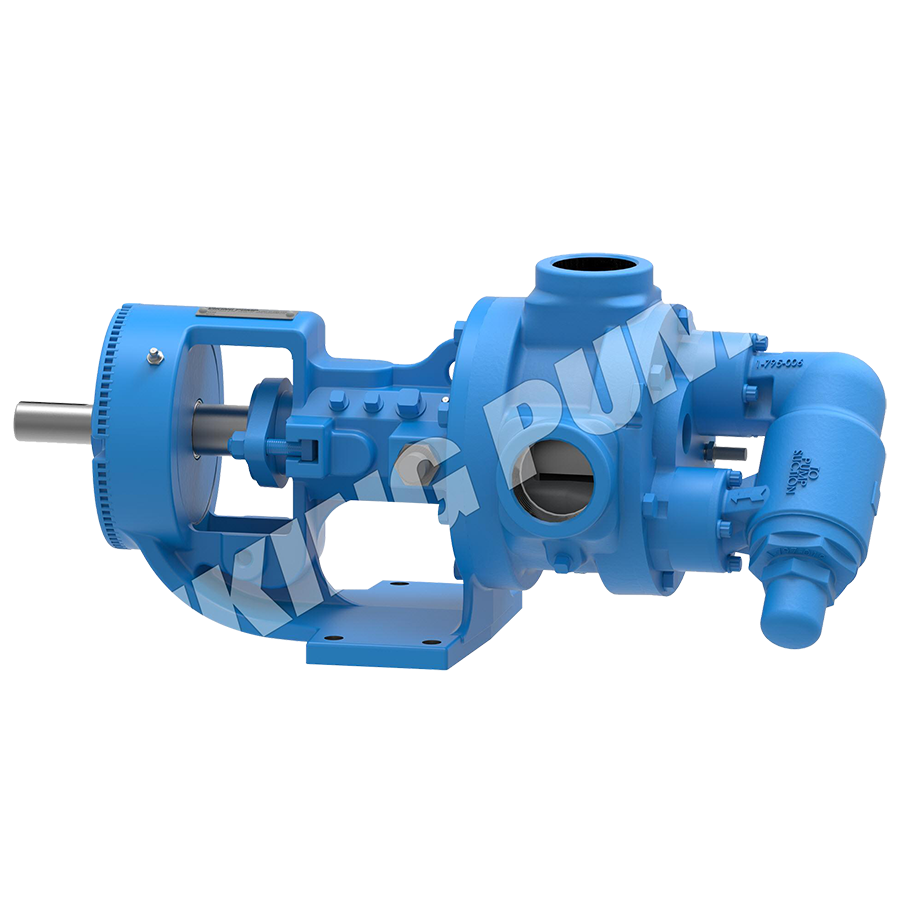

- Limiting pressure ratings helps extend pump life on abrasives, by increasing film thickness between rotating parts and reduces the loads or forces within the pump.

- Limited speeds help ensure longest life by reducing fluid velocity, which reduces abrasion.

- All pumped liquid is contained in the casing area, which enables superior flushing to clean the casing.

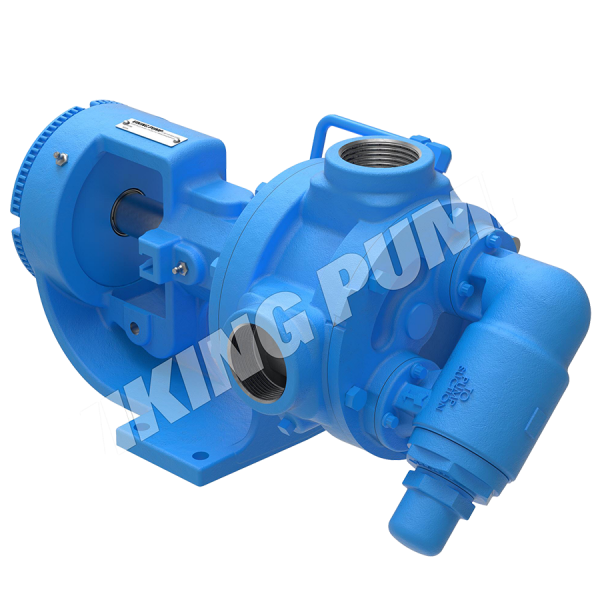

- Positive Displacement Internal Gear pumping principle handles a broad range of viscosities with constant flow rate.

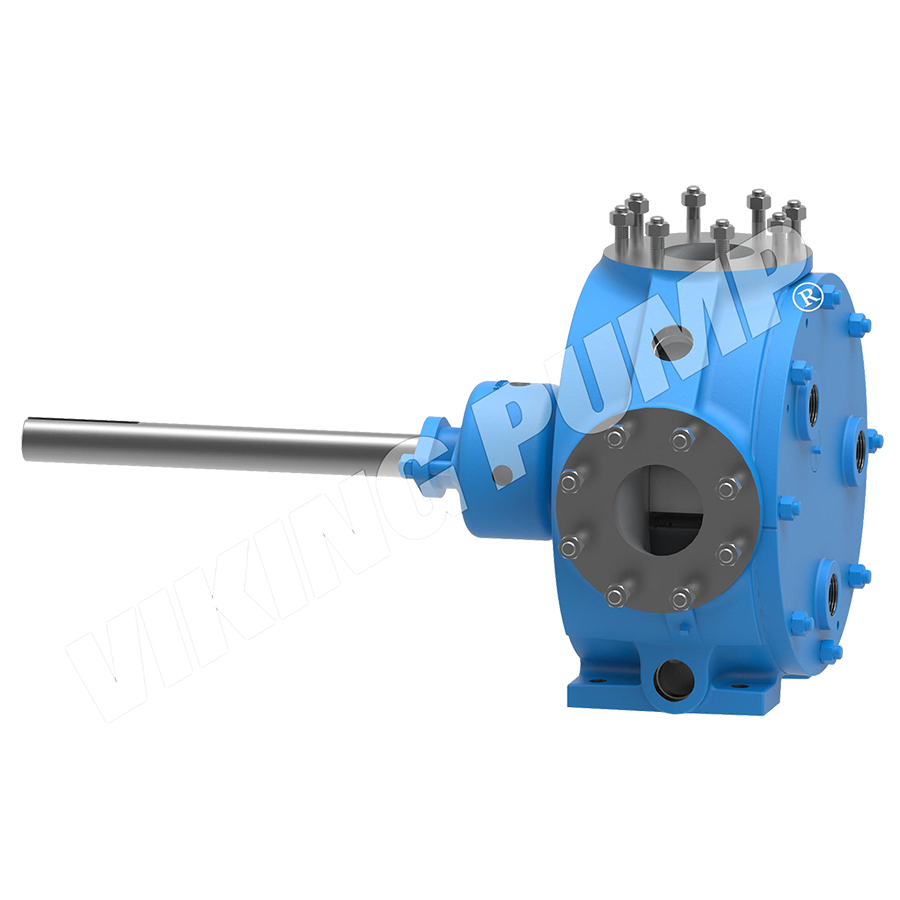

- Footed cast iron bracket provides rigid mounting to help maintain alignment, which extends seal and bearing life.

- Axial rotor thrust is controlled by double row ball or tapered roller bearings mounted in the rotatable bearing housing, which enables fast, easy end clearance adjustment.

- Can use direct drive, gear reducer or gearmotor drive, or belt-drive.

- Pressure relief valve is standard.

===========

CAPACITY: .75 to 182 GPM (.17 to 41 m3/h)

PRESSURE: to 150 PSI (0 to 10 Bar)

TEMPERATURE: -40 to +300 °F (-40 to + 150 °C)

VISCOSITY: 38 to 250,000 SSU (3 to 55,000 cST)

===========

TAN LONG TECHNOLOGY SOLUTIONS CO., LTD

Address: 146/18 Nguyen Huu Tho, Phưoc Kien, Nha Be, HCMc, VN

Phone: (+84)-8 3781 5635/36/37

Email: sales@tanlongvietnam.com | contact@tanlongvietnam.com

Website:www.tanlongvietnam.com