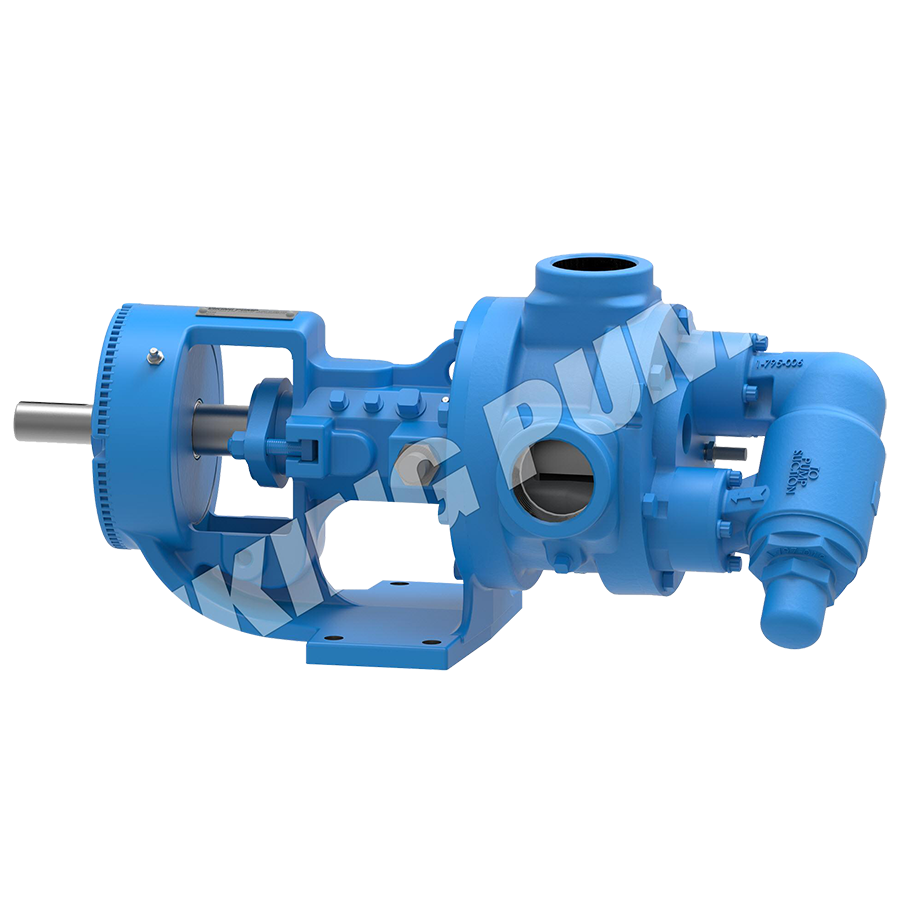

Description

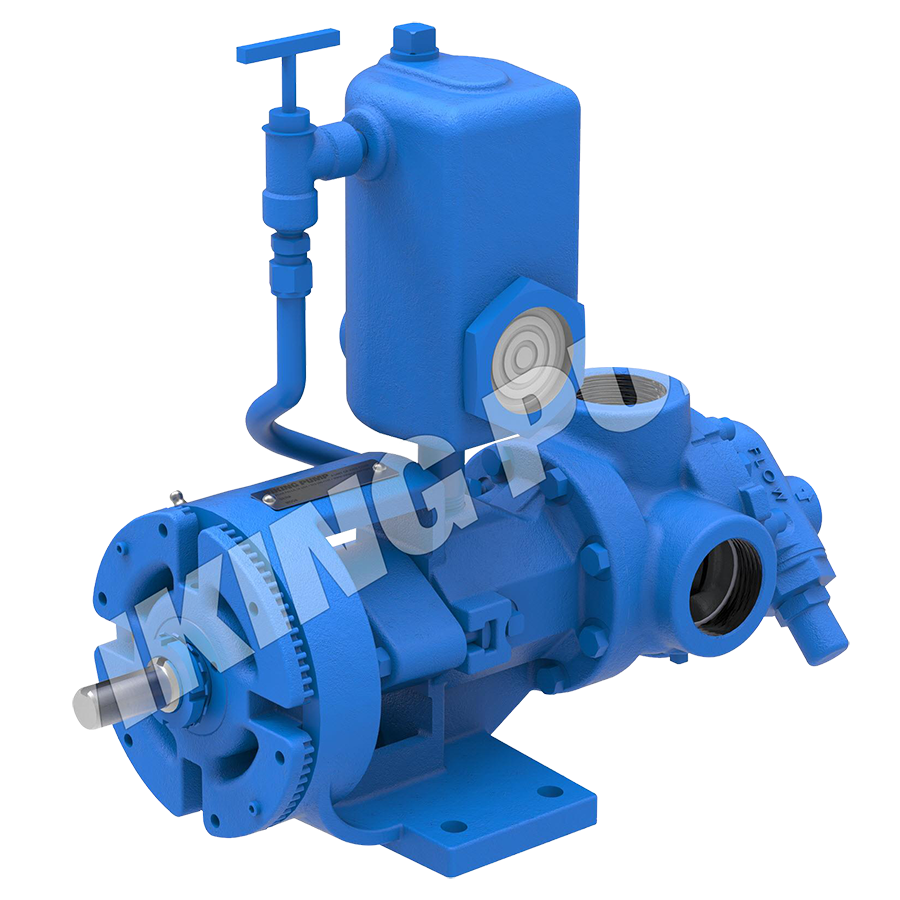

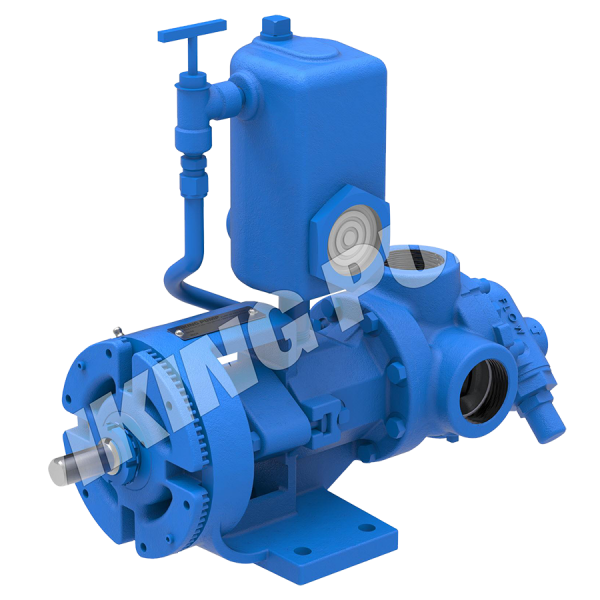

DOUBLE DYNAMIC SEALING

The double mechanical seals provide carbon graphite rotating faces against Ni-Resist stationary seats. Ni-Resist is a metallic face which can be replaced without concern for hairline cracks that can occur when installing ceramic or silicon carbide seals, another safety feature. The area between the inboard and outboard mechanical seals is filled with refrigeration oil supplied by a reservoir mounted above the pump. A unique flush line with valve carries ammonia from behind the rotor to the reservoir, pressurizing the barrier oil to the same pressure seen by the seal inside the pump. The outboard seal sees only oil, and provides a secondary barrier should the inboard seal begin to leak.

The reservoir may be filled with oil using a port on the top, or, an optional filling valve on the side of the pump permits refilling during pump operation. A sight glass allows visual inspection of oil level.

The benefit of double mechanical seals versus sealless magnetic drives is that it is inherently more efficient, requiring less power, because mag drive pumps require recirculation (slip) through the canister area to remove heat generated by eddy currents.

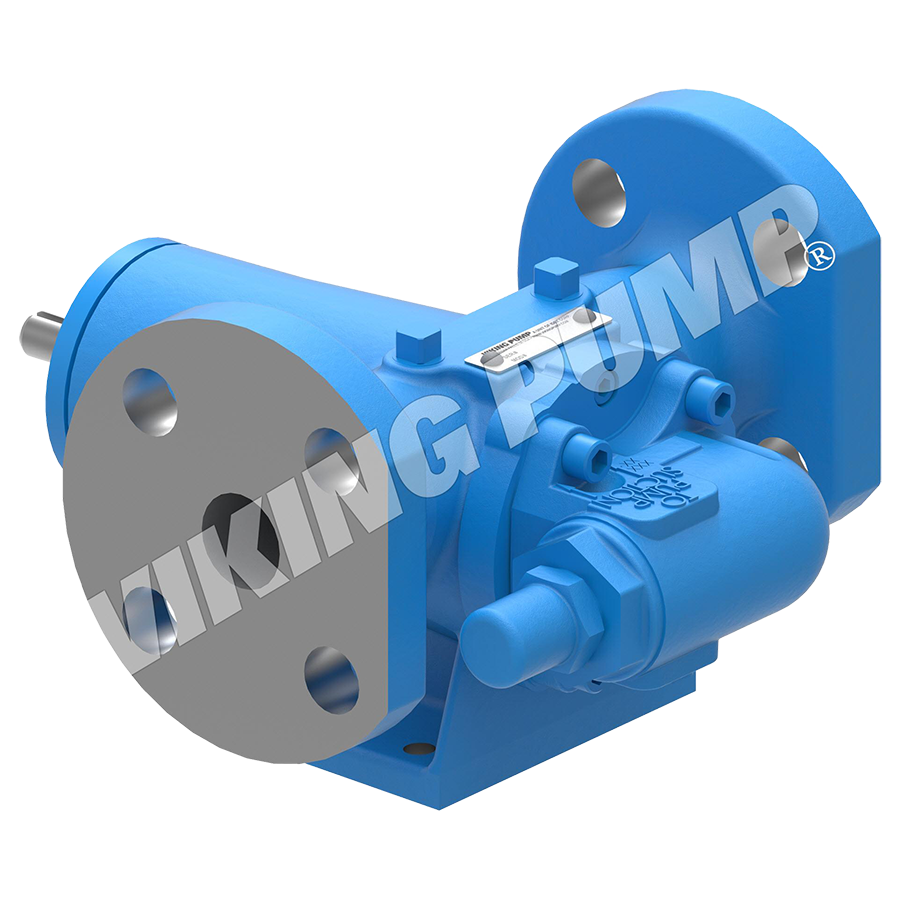

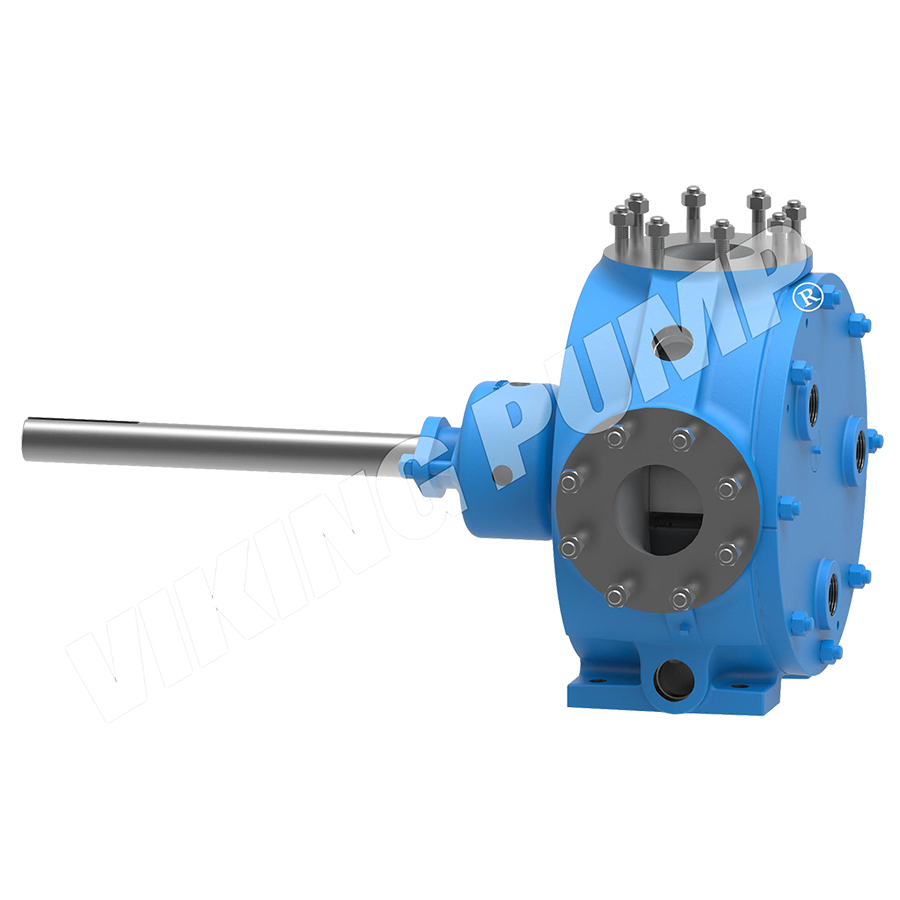

END CLEARANCE ADJUSTMENT

The 4924A Series™ replaced Viking’s OLD 4925 Series™ Ammonia pumps. The key difference is the bearing housing on the bracket simplifies adjusting end clearance, which helps ensure optimal efficiency and can compensate for wear over time. With this design, you simply rotate the bearing housing clockwise until it stops, then back it off the distance recommended in the Technical Service Manual (TSM 1467) to set the end clearance, and lock it down. The old style required rotating two bearing end caps and measuring end clearance

PRESSURE RELIEF

Positive displacement pumps must be fitted with a pressure relief device to prevent overpressure. Viking’s 4924A Series™ pumps are supplied with a Return-To-Tank (RTT) Pressure Relief Valve (PRV) as standard, which routes ammonia from any overpressure situation back to the tank.

OPTIONAL FEATURES

(Specify these special features when ordering)

- Sight Glass with Frost Shield.

This prevents the sight glass from being covered with frost when the pumping unit is installed in a cold room. - Filling Valve.

A filling valve can be furnished to permit easy refilling of oil reservoir without stopping pump. - Oil Reservoir Heater. (Not Illustrated)

An electric immersion type heater to provide adequate reservoir oil temperature if pumping unit is installed in a cold room.

===========

CAPACITY: .10 to 60 GPM (2.3 to 13.6 m3/h)

PRESSURE: to 50 PSI (to 3.5 Bar)

TEMPERATURE: -40 to +225 °F (-40 to +107 °C)

===========

TAN LONG TECHNOLOGY SOLUTIONS CO., LTD

Address: 146/18 Nguyen Huu Tho, Phưoc Kien, Nha Be, HCMc, VN

Phone: (+84)-8 3781 5635/36/37

Email: sales@tanlongvietnam.com | contact@tanlongvietnam.com

Website:www.tanlongvietnam.com