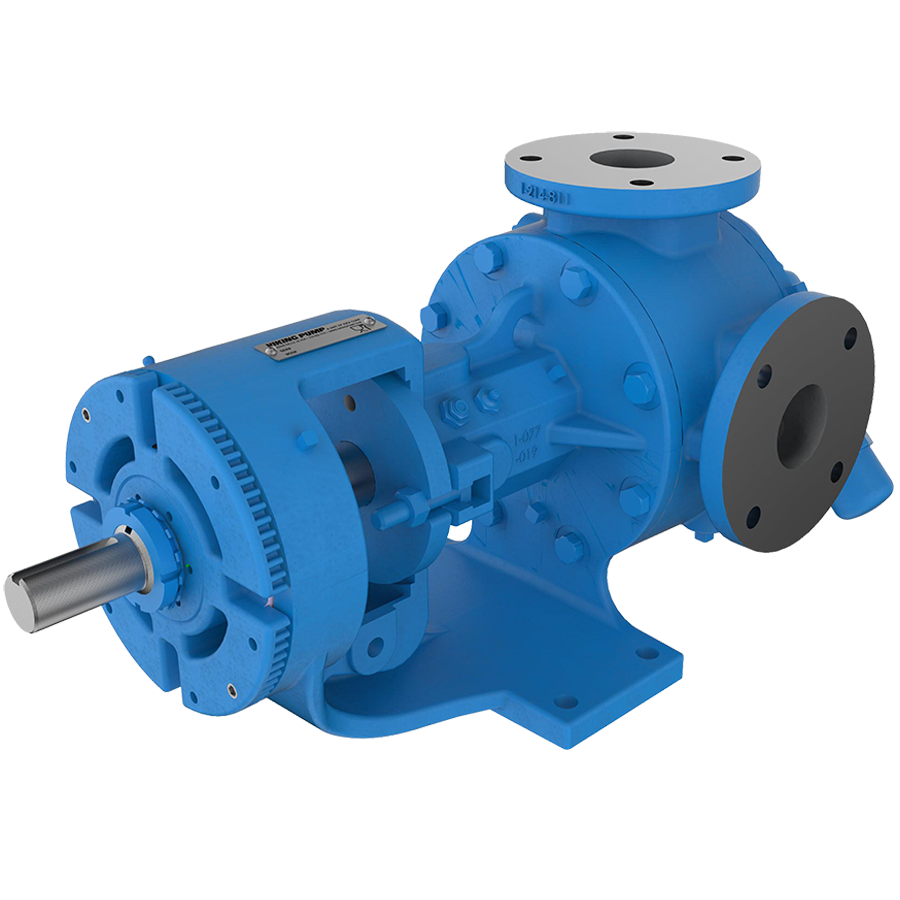

Description

FEATURES & BENEFITS

- Positive Displacement Internal Gear pumping principle handles a broad range of viscosities with constant flow rate

- Axial rotor thrust is controlled by double row ball bearing or tapered roller bearings; a bushing provides a secondary point of radial shaft support

- Rotatable bearing housing provides easy rotor end clearance adjustment for viscosity or to compensate wear

- Numerous material options are available for bushings, idler pins, shafts, rotors, idlers and elastomers

- Gear and pump geometry has been optimized based on more than 100 years of experience

- Footed cast iron bracket provides rigid mounting to help maintain alignment, which extends seal and bearing life

- Can use direct drive, gear reducer or gearmotor drive, or belt-drive

- Pressure relief valve standard on all except RS size pumps; less valve / plain head option available

- Series designed with an enlarged bearing housing. Used in conjunction with a spacer coupling permits easy cartridge seal or O-Pro™ Barrier Seal installation and removal in place without removing the head and rotor/shaft.

- Seal options include packing, O-Pro™ Barrier Seal, single component seals, cartridge lip seals and cartridge single and double mechanical seals. Various seal flush plans are available.

===========

CAPACITY: 70 to 140 GPM (23 to 32 m³/h)

PRESSURE: to 200 PSI (14 BAR)

TEMPERATURE: -60 to +450 °F (-51 to +230 °C)

VISCOSITY: 28 to 2,000,000 SSU (1 to 550* cST)

===========

UNIVERSAL PRODUCT LINE:

CAST IRON – NON-JACKETED PUMPS